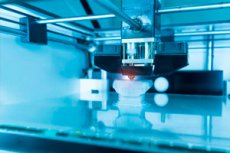

一种新的 3D 药物打印技术可以将多种药物打印成一颗药丸,为按计划服用剂量的个性化药丸铺平了道路。

诺丁汉大学增材制造中心的研究人员与药学院合作,利用多功能喷墨3D打印技术(MM-IJ3DP)研制出个性化药物。该研究成果已发表在《材料今日进展》杂志上。

该团队开发了一种先进的方法,可以创建具有定制药物释放特性的个性化药片,为患者提供更精确、更有效的治疗选择。

多功能喷墨3D打印(MM-IJ3DP)可以打印出根据药片设计决定的、以可控速率释放药物的药片。这得益于一种基于对紫外线敏感的分子的新型墨水配方。打印时,这些分子会形成水溶性结构。

药物释放速率由药片独特的内部结构控制,从而可以确定剂量释放的时间。这种方法可以将多种药物打印到单个药片中,从而简化复杂的单剂量给药方案。

领导这项研究的工程学院增材制造中心助理教授何因锋博士表示:“这是个性化医疗发展中令人兴奋的一步。这一突破不仅凸显了3D打印革新药物输送的潜力,也为下一代个性化医疗的发展开辟了新的途径。”

“尽管这项技术前景光明,但也面临挑战,例如需要更多配方来支持更广泛的材料。正在进行的研究旨在改进这些方面,从而提升 MM-IJ3DP 的广泛应用潜力。”—— Ricky Wildman 教授

这项技术对于制造需要在特定时间释放药物的药物尤其有用,使其成为治疗那些重视时间和剂量精准度的疾病的理想选择。单批次打印56片药片的能力证明了该技术的可扩展性,为个性化药物的生产提供了巨大的潜力。

诺丁汉大学药学院的费利西蒂·罗斯教授是该研究的共同作者之一,她表示:“处方药的未来是个性化的。我们知道,英国高达50%的人没有正确服药,导致病情不受控制或治疗不当,进而影响健康。单片药片的给药方式可以更轻松地在不同时间服用多种药物,这项研究是朝着这个方向迈出的激动人心的一步。”